Lenterra InLine Rheometer

Drag Force Flow (DFF) Sensors

Lenterra’s DFF sensor is an immersion probe that provides continuous real-time measurement of flow force and temperature in liquids and powders. This novel Process Analytical Technology (PAT) tool is the basic part of Lenterra Inline Rheometer (LIR) that enables process monitoring and control in pharmaceutical, food, biotech and other industries.

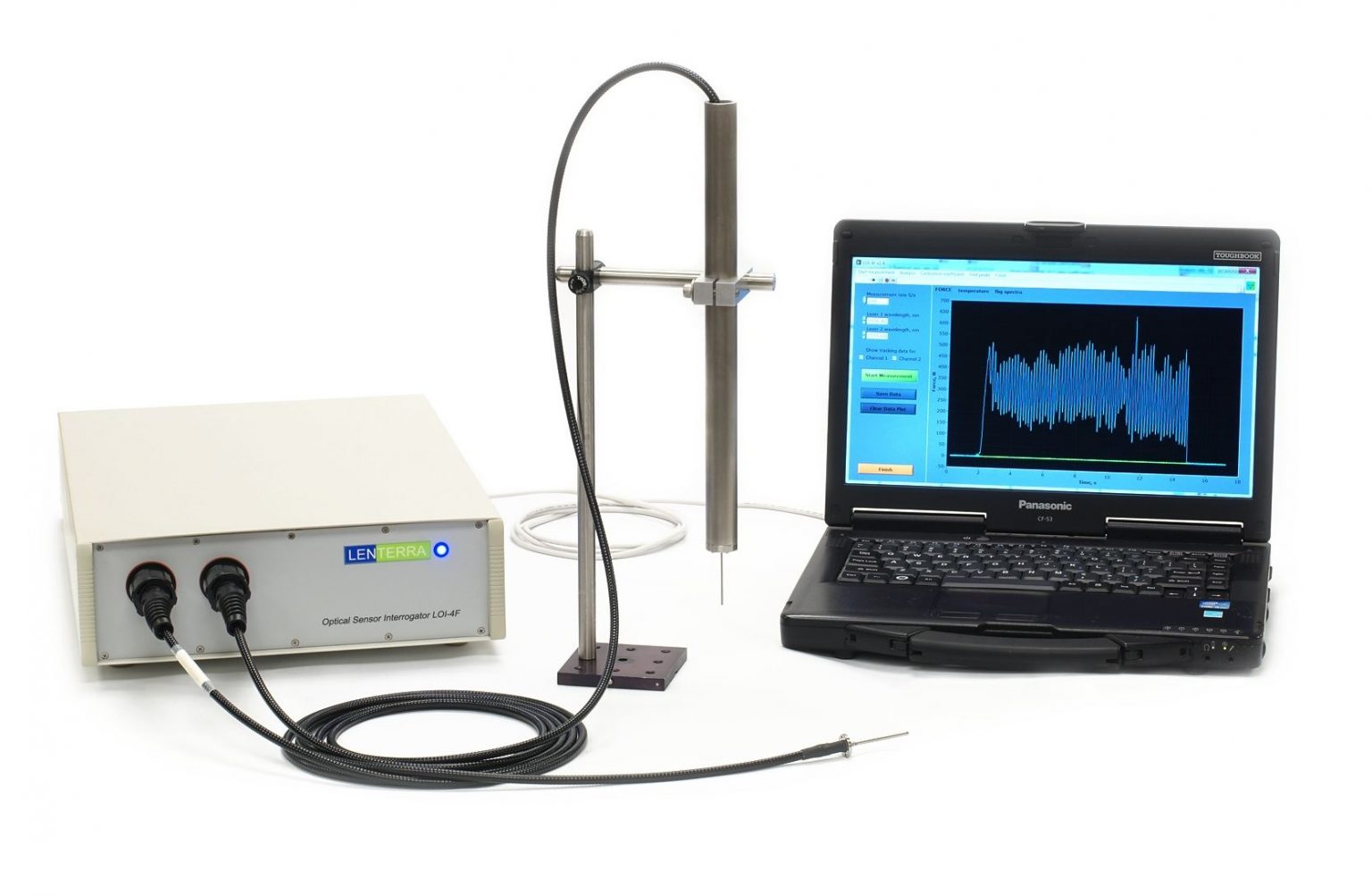

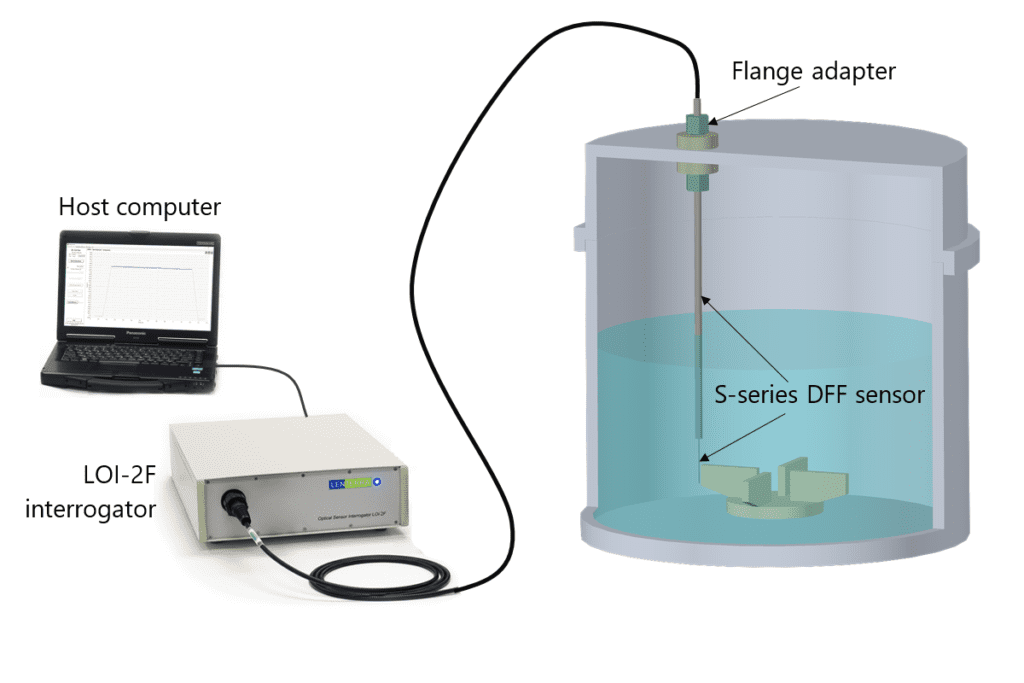

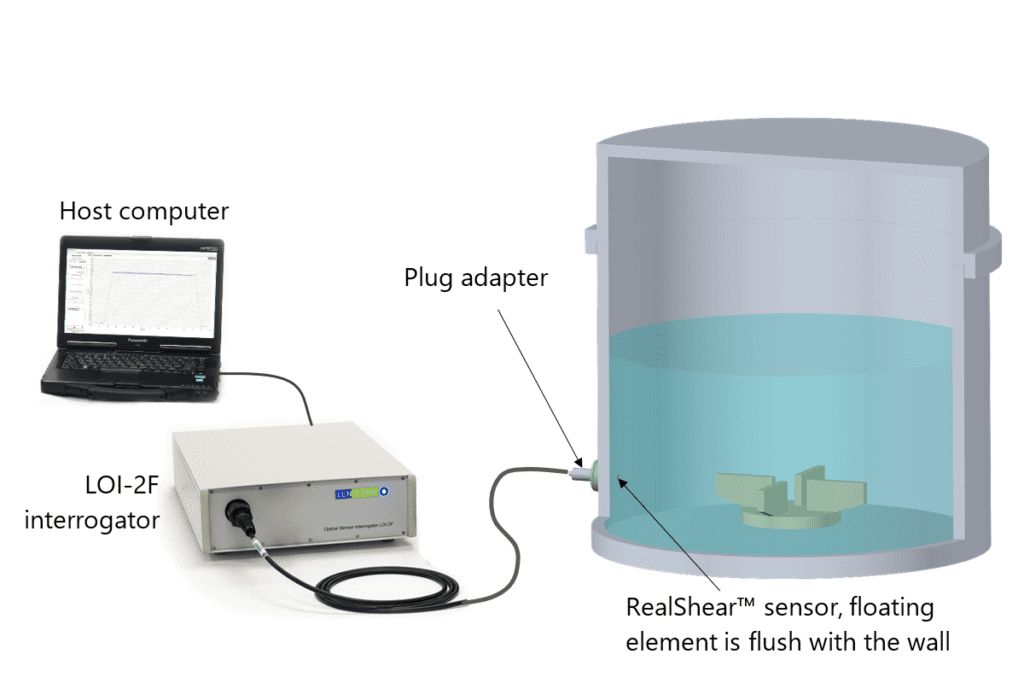

Depending on configuration, LIR consists of one or two Lenterra’s sensors (Drag Force Flow (DFF) or RealShearTM), an LOI optical interrogator and a host computer with control, measurement and data processing software. The probe placed in a desired location within the processing equipment is connected to the interrogator via fiber-optical cable. To install the probe into an apparatus, an adapter is required.

There are two basic types of LIR configurations that are determined by the type of the interrogator – a one channel LOI-2F and a two channel LOI-4F. There are total of six different configurations of LIR specified below. They are customizable, and could be converted one into another by replacing the sensor. Each configuration includes a rugged laptop pre-installed with measurement and post processing software. The LENFLOW measurement software supports all LIR configurations.

This basic LIR configuration includes one DFF sensor that can be placed in various places inside the processing equipment, for example next to an agitator blade of a mixer as depicted in the figure. Depending on the flow speed and nature of the material, a DFF sensor with required sensitivity should be selected. A standard or custom adapter can be used.

This configuration can be used for measuring flows of any type of the material—liquids or powders, slurries or gases. LIR-D directly outputs temperature and flow force, as well as FPM and PCF metrics that characterize the densification and cohesiveness for powder flow, or flow velocity and viscosity for liquids.

This configuration is used for measuring wall shear stress exerted by liquids on the construction wall. The example on the figure illustrates installation of the sensor through a side port of a bioreactor or mixer. The sensor may also be installed through a pipe wall, or used with installed inline flexible T-Junction or flow cell.

This configuration is intended for use with liquid materials which do not contain a particulate phase. LIR-R outputs wall friction force, wall shear stress and temperature. For rotor-stator mixers, it also outputs viscosity.

Copyright GAMP Services 2024. All Rights Reserved.

Copyright GAMP Services 2024. All Rights Reserved.