21-CFR-11 Compliance Project

Revamp, Upgradation & Retrofitting -21-CFR-11 Compliant Project

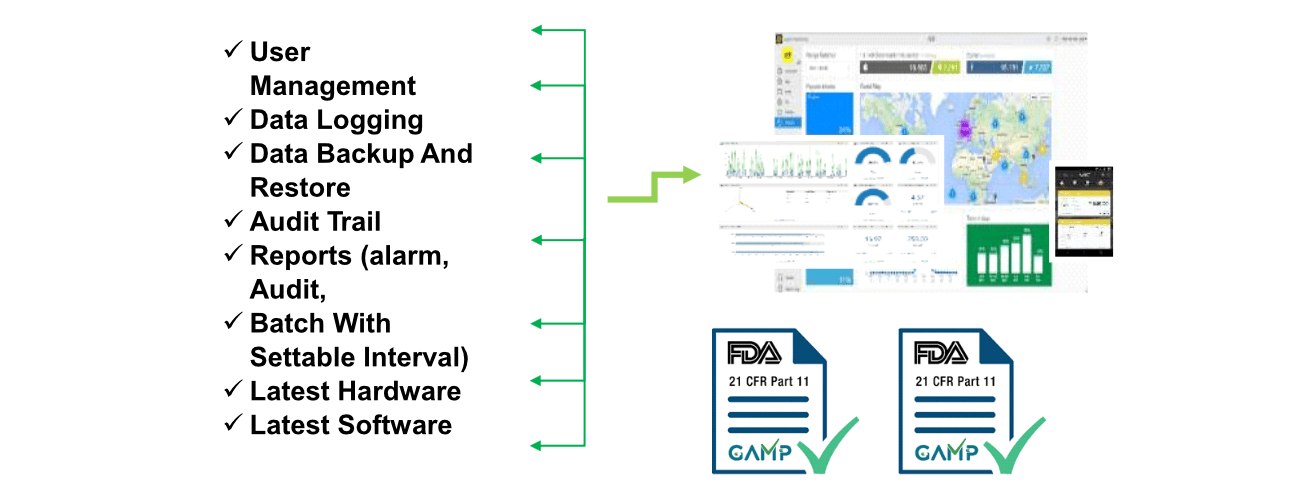

GAMP Group has developed considerable technical expertise for Revamp & Upgradation of 21-CFR-11 Compliant Upgradation Project throughout its history.. GAMP Group offers Revamp ,Retrofitting & Upgradation services for any equipment of any brand under 21-CFR-11 Compliant Upgradation Projects.

21-CFR-11 Compliant Upgradation Project or Revamp, Retrofitting & Upgradation Projects may be necessary to comply with up-to-date industry regulations and standards. Older Equipments may not meet current safety and efficiency requirements, which can result in financial loss (or penalties) for the company. Revamp ,Retrofitting & Upgradation allows companies to meet these updated requirements and ensure they are operating safely and efficiently.

Another reason to consider Revamp, Retrofitting & Upgradation is to improve the GAMP 5 Compliance of the All equipments under 21-CFR-11 Compliant Upgradation Project. Over time, a company’s production demands can increase, which means their equipments may not be large or efficient enough to meet their needs. Revamp, Retrofitting & Upgradation can include the installation of additional capabilities, such as an automatic loading and unloading system, to improve its efficiency and reduce downtime.

CFR-11 Compliant Upgradation Project

We use Branded PLC + HMI + SCADA like Siemens, Rockwell, Mitsubishi for our 21-CFR-11 Upgradation Project.

We have a team of 12 Experience Automation Engineers with GMP and GAMP Compliance and Regulatory understanding.

GAMP Group has expertise in Upgradation of Parenteral, API & Formulation Equipments

- Washer, Tunnel, Filling, sealing, capping M/c.

- Steam Sterilizers

- Freeze Dryers

- Manufacturing Vessels

- SIP/CIP Unit

- Part Washer

- Fumigators H2O2

- Leak Testing

- Visual Inspection M/C etc.

Solid Oral Machineries

- Compression Machines

- FBDs, FBEs

- RMG

- Blenders

- Spray Dryer etc.

- Packing Machineries

- Blister Pack

- Tablet Counting Machine

- Labelling Machine

- Check Weigher

- Labelling M/C etc.

Utility Machineries

- EMS/BMS System

- AHUs and Dehumidifiers

- Water Pre-treatment Plant

- R.O. Plant

- P.W Generation & Loop System

- WFI Generation & Loop System

- Pure Steam Generation etc.

Copyright GAMP Services 2024. All Rights Reserved.

Copyright GAMP Services 2024. All Rights Reserved.