For many of us, our direct experience with a semiconductor fabrication facility is limited to meeting rooms, cleanrooms, and analytical laboratories. However, these facilities are part of a much more complex infrastructure that houses regulatory, production, and delivery systems for various services and utilities essential for fab operations.

This section discusses fab utility systems, including ultrapure water, high-purity gases, exhaust gas treatment, and ultra-clean air systems, and how MKS’s portfolio is employed in these areas.

Ultrapure water (UPW) is essential for many semiconductor processes, including wafer cleaning, rinsing, surface conditioning, wet etching, and chemical mechanical planarization (CMP). CMP, in particular, consumes large amounts of UPW for slurry production and rinsing.

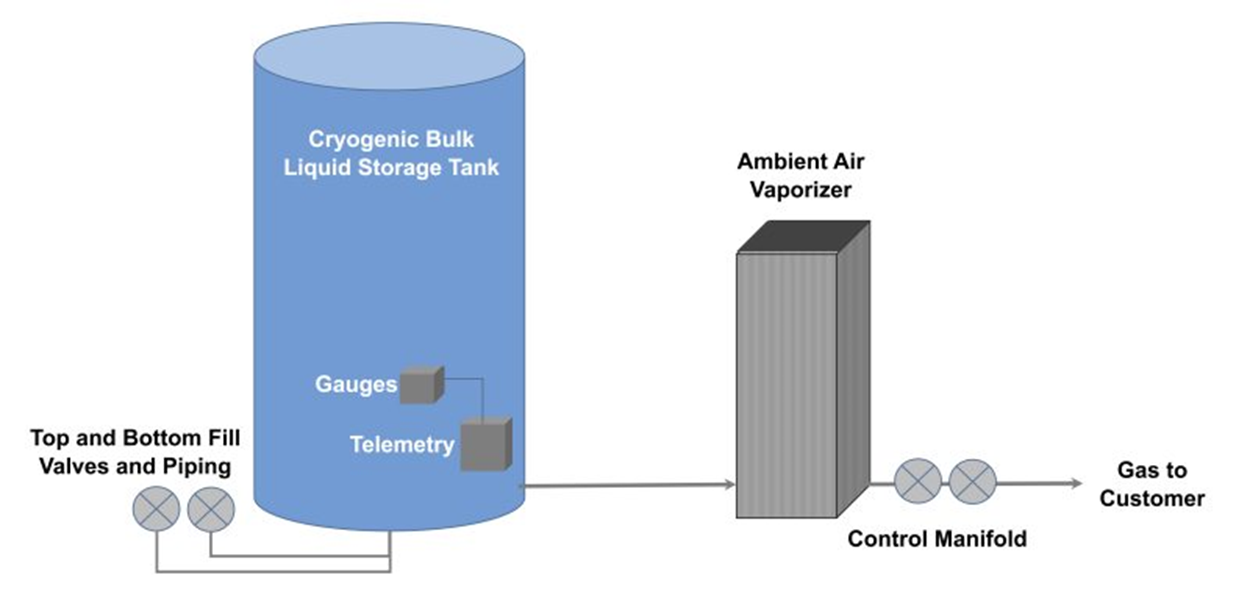

Semiconductor fabs require high-purity gases, such as nitrogen and argon, with purity maintained throughout distribution. Some gases also require point-of-use purification to ensure ultra-low contamination levels.

Process exhaust from cleaning, deposition, and metal etch operations may experience fouling from condensate buildup. To mitigate this, fabs employ vacuum components with controlled surface temperatures and chemical scrubbing systems for safe gas disposal.

Maintaining ultra-clean air conditions is critical in semiconductor fabs to minimize particulate contamination. Advanced air purification and handling systems ensure ultra-low particulate levels in production environments.