Injectable Plant Equipment Upgradation

Revamp ,Upgradation & Retrofitting -Injectable Plant Equipment

GAMP Group has developed considerable technical expertise for Revamp & Upgradation of Injectable Equipment throughout its history.. GAMP Group offers Revamp ,Retrofitting & Upgradation services for complete Injectable Equipments of any brand.

Injectable Equipment Revamp ,Retrofitting & Upgradation may be necessary to comply with up-to-date industry regulations and standards. Older Injectable Equipments may not meet current safety and efficiency requirements, which can result in financial loss (or penalties) for the company. Revamp ,Retrofitting & Upgradation allows companies to meet these updated requirements and ensure they are operating safely and efficiently.

Another reason to consider Revamp ,Retrofitting & Upgradation is to improve the capacity of the Injectable Equipment. Over time, a company’s production demands can increase, which means their Injectable Equipment may not be large or efficient enough to meet their needs. Revamp ,Retrofitting & Upgradation can include the installation of additional capabilities, such as an automatic loading and unloading system, to improve its efficiency and reduce downtime.

There are many reasons why an Injectable Equipment may require Revamp ,Retrofitting & Upgradation services, from repairing damaged components to improving safety, efficiency, capacity and compliance with updated regulations.

We have expert team for Mechanical, Electrical, Piping and Control System Upgradation for :

We offer complete Package from Intial Design Review, Proposed Solution, Modification & Upgradation, Commissioning & Validation (CQV Package) as well as Software Validation.

For Thermal Validation, We use KAYE Validator AVS as well as we offer complete cycle development for Autoclave, Lyophilizer, Sterilizing Tunnel, CIP/SIP Skid and Isolator.

In Nutshell, The main objective of Revamp ,Retrofitting & Upgradation in Injectable Equipments is to improve their performance and extend their useful life, while saving time and money compared to buying a new Injectable Equipment.

- Autoclave

- Washing Machine

- Sterilizing Tunnel

- Lyophilizer

- Filling Line

- CIP/SIP Skid

- Isolator

- Packing Lines

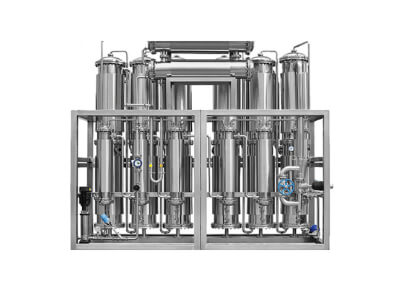

- WFI Plant

- Utilities Plant

As a preliminary step, GAMP Group offers a consulting service in which its electrical, mechanical and software engineering teams jointly analyse drawings and the state of the machine in order to offer an optimal and personalized solution.

The scope of the update can vary from the modernization of elementary systems such as the PLC, software, hardware or control system, to a complete renovation that includes the update of vacuum systems, exchangers, valves and sensors.

These works, through a process that can be carried out at GAMP Group’s or customer’s facilities, will bring these Injectable Equipments to the latest technology available on the market.

At the end of the Revamp ,Retrofitting & Upgradation process, the equipment is fully updated, tested and certified by GAMP Group, guaranteeing its efficiency, safety, capacity and functionality. Then GAMP Group do complete CQV Process to validate the Equipment.

At GAMP Group, we offer a wide range of Revamp ,Retrofitting & Upgradation services to meet the unique needs of each client, ensuring that your Injectable Equipment is performing at the highest possible level.

Revamp ,Retrofitting & Upgradation control systems and software in Injectable Equipments can also improve traceability and monitoring of processes, allowing greater efficiency and productivity in production. With our 21-CFR -11 Compliance software, you will be able to record, control and access all the data of your processes easily and quickly, which will allow you to identify possible problems and take fast action if required.

Revamp ,Retrofitting & Upgradation control systems and software is a long-term investment that can significantly improve the efficiency, safety, and productivity of your Injectable Equipment.

At GAMP Group, we are committed to providing a high-quality service so that your equipment meets the required standards and can function safely and efficiently for many more years.

The importance of having the best team

Our highly trained team, with extensive experience in the sector, is always happy to advise you so that you can make the best decision that meets your needs. No matter the brand or model of your Injectable Equipment, at GAMP Group we are prepared to carry out the Revamp ,Retrofitting & Upgradation that your equipment requires, managing to improve its performance, increase its efficiency and prolong its life.

Copyright GAMP Services 2024. All Rights Reserved.

Copyright GAMP Services 2024. All Rights Reserved.