Temperature Mapping

Temperature distribution in Open and Closed chamber

The enclosure temperature mapping of a cooking cell or a pasteurization tunnel identifies the cold / hot spots of your equipment. This also gives you the range of temperature dispersion of the equipment and confirms or denies the possibility of using it.

The use of a large number of loggers makes it possible to qualify the temperature distribution, the repeatability of the cycle as well as the impact of the load and its variations. The study is aimed at all kinds of thermal equipment whose function is to provide cooking, or product stability by pasteurization, cooking or even sterilization (see Retort thermal mapping information).

All the measures are included in a clear and detailed report to meet the expectations of your clients (certifiers, large retailers, players in the food industry). We uses different sensor technologies to ensure that you always use the one that is best suited to your equipment.

Retort Thermal Mapping

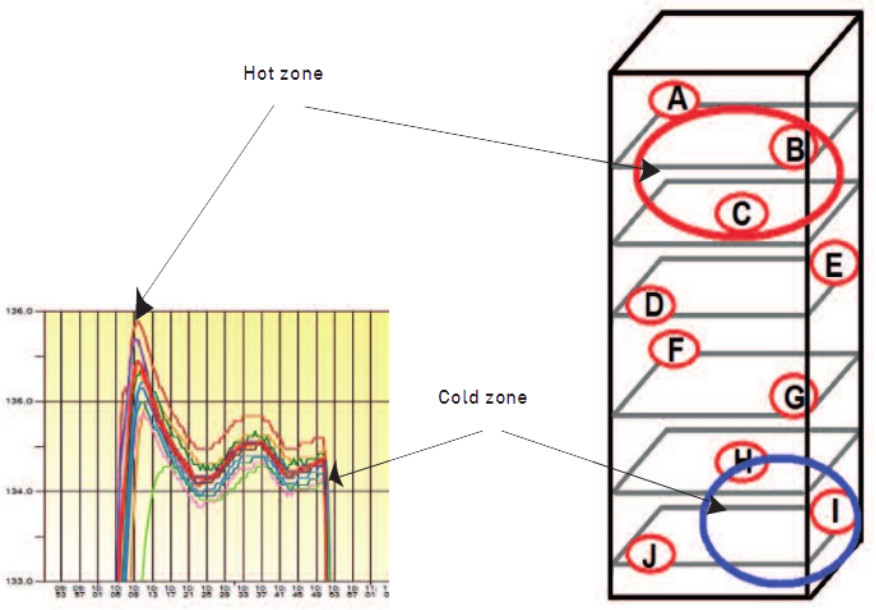

Retort mapping must result in a report that positively meets the specifications required by your client (certifier, retailer or food industry players) or a heavy maintenance operation. Moreover, the total dispersion must not exceed the degree during the pasteurisation or sterilisation stage and this is not always the case. So what to do?

Our exclusive method gives you a solution:- check and adjust the metrology of the measuring instruments of your food retort.

- map the temperatures of the chamber and make them homogeneous if necessary by various adjustments (schedule, regulation mode, power of the energy networks, …).

- identify the cold and the hot spots.

- check the repeatability of the device.

- check the correspondence of the performances with the specifications.

- quickly produce a clear and detailed report validating the industrial operation of the retort.

Understanding what the process target is. Technical staff often target a specific temperature for a specific time. It’s usually the minimum level of heat treatment required to achieve a specific log reduction of a target organism, plus extra heating to give a margin of safety. Therefore, we recommend understanding and challenging a) the heat resistance of the organism targeted and b) the margin of safety specified. It’s possible you could reduce processing time with this understanding, or even experiment with time/temperature combinations that better suit your product. Knowing the different validation techniques. Temperature measurement is the most common method to validate a thermal process. However, there are a variety of different sensors and probes/thermocouples which can be used depending on your product type and heating environment. We can provide advice as to what the best temperature measurement solutions are for your process type or we can explore other validation methods (e.g. by using surrogate microorganisms or enzymic methods).

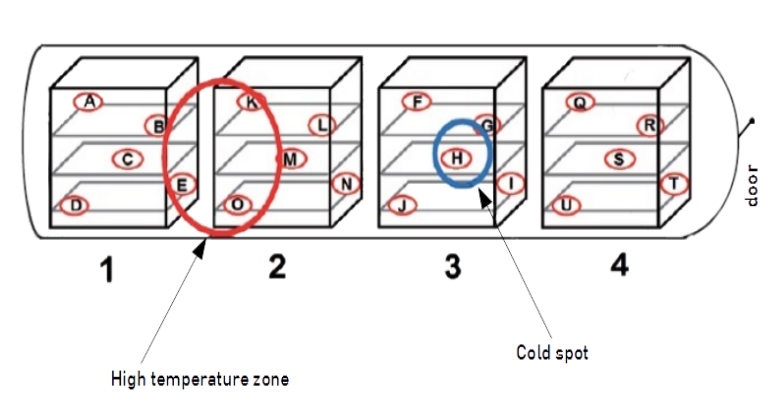

Establishing where to position a probe and product sample. The exact point in the product where temperature measurement is being recorded is crucial as often within a pack, or within a unit of product, heating rates can vary (for example in a chicken drumstick heating rates by the bone are different to those in the flesh). It is a similar case with the positioning of validation samples within the heating system, for example, in a retort the top layer of a crate may heat very differently to the bottom layer, or racks of product by an oven door may heat at a different rate to those away from the door. Often extra testing is required to understand these crucial points fully.

Understanding the ‘worst-case’ variables of a process. When undertaking validation test runs, you need to understand how the amount of heat applied to your product may vary from day to day. This could be due to variations within the product, packaging or the cooking vessel. For example, the fill level of a drinks bottle, or the heating performance of a retort. These variables need to be controlled and set to replicate the ‘worst-case scenario’ of heating conditions during the validation run. This ensures an absolute minimum level of heat treatment will always be applied during normal production.

Interpreting validation data. A large amount of data is generated during a robust thermal validation. When analysing the data to calculate minimum P or F0 values, several questions can crop up: Which part of the cook program or cycle should be used to calculate the lethality?

If different areas of the retort or cooker vary, with large differences in temperature, what level of difference is acceptable? The P/F0 values are extremely variable, how can I be sure they will always be high enough?

Would it be sensible to apply a safety factor and over process the product? If so, by how much? If you struggle with any of these challenges, or want to validate or optimise your thermal process, contact our processing support team.

Control System Validation Services- “Part 11” Compliance The team of GAMP services can provide expert level software and services when it comes to Validating your new or existing control system to ensure compliance with FDA’s 21 CFR 11 which regulates the use of electronic records and electronic signatures. We follow the guidelines to validate the retort/control system, and then confirm that the system complies with all requirements of Part 11 such as user security/access, change control and audit trails, and data integrity. Upon completion, a complete Validation Report will be issued, documenting your systems compliance with 21 CFR Part 11.

We’ve compiled the key challenges of validating a process to help you overcome them:

- Understanding what the process target is. Technical staff often target a specific temperature for a specific time. It’s usually the minimum level of heat treatment required to achieve a specific log reduction of a target organism, plus extra heating to give a margin of safety. Therefore, we recommend understanding and challenging a) the heat resistance of the organism targeted and b) the margin of safety specified. It’s possible you could reduce processing time with this understanding, or even experiment with time/temperature combinations that better suit your product.

- Knowing the different validation techniques. Temperature measurement is the most common method to validate a thermal process. However, there are a variety of different sensors and probes/thermocouples which can be used depending on your product type and heating environment. We can provide advice as to what the best temperature measurement solutions are for your process type or we can explore other validation methods (e.g. by using surrogate microorganisms or enzymic methods).

- Establishing where to position a probe and product sample. The exact point in the product where temperature measurement is being recorded is crucial as often within a pack, or within a unit of product, heating rates can vary (for example in a chicken drumstick heating rates by the bone are different to those in the flesh). It is a similar case with the positioning of validation samples within the heating system, for example, in a retort the top layer of a crate may heat very differently to the bottom layer, or racks of product by an oven door may heat at a different rate to those away from the door. Often extra testing is required to understand these crucial points fully.

- Understanding the ‘worst-case’ variables of a process. When undertaking validation test runs, you need to understand how the amount of heat applied to your product may vary from day to day. This could be due to variations within the product, packaging or the cooking vessel. For example, the fill level of a drinks bottle, or the heating performance of a retort. These variables need to be controlled and set to replicate the ‘worst-case scenario’ of heating conditions during the validation run. This ensures an absolute minimum level of heat treatment will always be applied during normal production.

- Interpreting validation data. A large amount of data is generated during a robust thermal validation. When analysing the data to calculate minimum P or F0 values, several questions can crop up:

- Which part of the cook program or cycle should be used to calculate the lethality?

- If different areas of the retort or cooker vary, with large differences in temperature, what level of difference is acceptable?

- The P/F0 values are extremely variable, how can I be sure they will always be high enough?

- Would it be sensible to apply a safety factor and over process the product? If so, by how much?

Control System Validation Services- “Part 11” Compliance

The team of GAMP services can provide expert level software and services when it comes to Validating your new or existing control system to ensure compliance with FDA’s 21 CFR 11 which regulates the use of electronic records and electronic signatures. We follow the guidelines to validate the retort/control system, and then confirm that the system complies with all requirements of Part 11 such as user security/access, change control and audit trails, and data integrity. Upon completion, a complete Validation Report will be issued, documenting your systems compliance with 21 CFR Part 11.

Food Analysis & Quality Control

The SpectraAlyzer FOOD is the ideal solution for routine food analysis of major quality parameters during food production.

Applications:

OIL AND OILSEEDS

Parameters / component– Analyzed- Oilseeds (Soybean, cottonseeds, groundnut, mustard, rice bran) – Moisture, Oil content, Fiber content, Ash, Carbohydrates, Acidity, Total soluble solids, Crude protein, Free Fatty acid, Sugar, Starch, Total fat.

- Oil (palm oil, mustard oil, cottonseed oil) – Free Fatty Acids,, Unsaponifiable matter, Iodine value, Saponification value, Peroxide value, Riechert Meissl Number

- Deoiled cake – Moisture, Oil content, Fibre, Ash, Protein, Silica

FOOD INGREDIENTS

Parameters / component– Analyzed- Fuit/Vegetable pulp – Moisture, total solids, acidity, °Brix, acetic acid, tartaric acid, oxalic acid, citric acid Pickles- Moisture, ash, pH, titrable acidity, salt, total sugar, fat

- Vinegar- Total acids, total solids, ash, total phenolic content, acetic acid, alcohol o Seasonings- Moisture, ash, acid insoluble ash, salt content

- Syrups- Total sugars, viscosity, refractive index

- Oil- Free Fatty Acids, iodine value, saponification value, peroxide value, RM Number Ketchup/Mayonnaise- Oil, moisture, dry matter, total soluble solids, acidity

- Soy sauce – Total nitrogen, salt, total soluble solids, acidity Tomato paste – Brix, beta-carotene, crudeness, fructose, glucose, lycopene

- Whole spices (seeds) – Moisture, Ash, Acid insoluble ash, Titrable acidity, Salt, Protein, Crude fibre

- Ground spices – Moisture, Ash, Acid insoluble ash, Scoville Heat Units (SHU), Total oil, Titrable acidity, Salt, Phytochemicals (curcumin, capsaicin, piperine), Oleoresins

- Whole Coriander – Moisture, Total Ash, Volatile oil, Acid insoluble ash.

- Whole Rajghara – Moisture, Total Ash, Acid insoluble ash, pH

- Turmeric Powder- Moisture, Total Ash, Acid insoluble ash, Curcumin, Ttal starch, pH, Protein, Carbohydrates, Fat, Fiber, Starch.

- Red Chilli Powder – Moisture, Total Ash, Acid insoluble ash, NVEE, Crude Fiber, Color Value, Capsaicin, Protein, Carbohydrates.

- Hing Powder- Moisture, Total Ash, Acid insoluble ash, Alcohol extract, Protein, Carbohydrates, Fiber, Energy, Fat.

- Coriander Cumin Powder- Moisture, Crude fiber, Volatile oil, Total Ash, Acid insoluble ash, NVEE, Protein, Carbohydrates, Dietry fiber.

- Dry Ginger Powder – Acid insoluble ash, Alcohol extract on dry basis, Cold water soluble extract on dry basis, Moisture, Total Ash, Volatile oil,

- Dry Mango Powder – Moisture, Total Ash, Acid insoluble ash, Acidity, Crude fiber.

- Hing Ras – Acid insoluble ash, Alochol extract, Moisture, Total Ash

SPICES

Parameters / component– Analyzed